The Role of Angle Board Products in Practical Applications

I. Introduction

In the world of packaging and shipping, angle board products play a crucial role in ensuring the safety and integrity of goods during transit. Defined as protective corner pieces made from various materials, angle boards are designed to shield the edges and corners of products from damage. Their importance spans across multiple industries, including manufacturing, retail, construction, and technology. This article aims to explore the various applications of angle board products, their key functions, benefits, challenges, and future trends, ultimately highlighting their significance in enhancing efficiency and protection in practical applications.

II. Understanding Angle Board Products

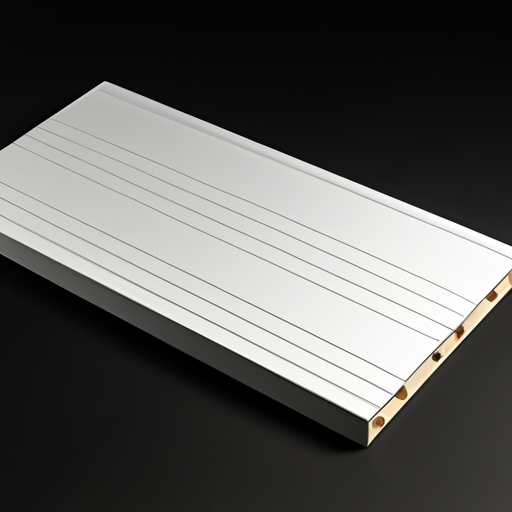

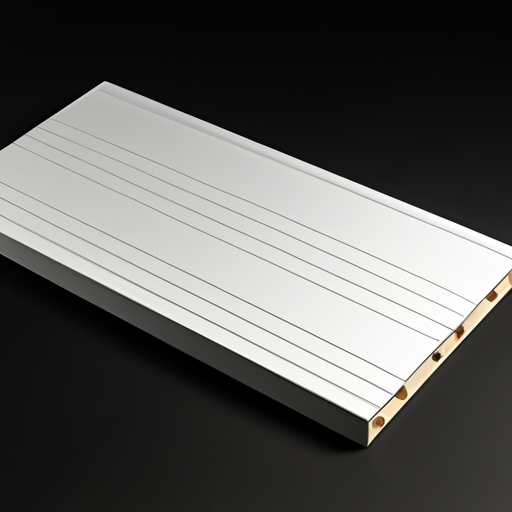

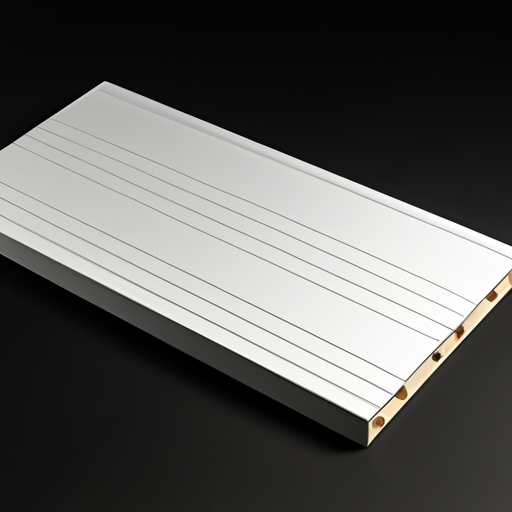

A. Description of Angle Boards

Angle boards, also known as corner protectors, are typically L-shaped or U-shaped structures that provide a protective barrier for the edges of products. They are made from a variety of materials, including cardboard, plastic, and metal, each offering different levels of durability and protection.

1. **Materials Used**:

- **Cardboard**: Lightweight and cost-effective, cardboard angle boards are commonly used for lighter products and are easily recyclable.

- **Plastic**: More durable than cardboard, plastic angle boards are resistant to moisture and can be reused multiple times, making them suitable for heavier items.

- **Metal**: Offering the highest level of protection, metal angle boards are used for extremely heavy or fragile products, providing robust support during shipping.

2. **Types of Angle Boards**:

- **L-shaped**: These are the most common type, designed to fit snugly around the corners of boxes or pallets.

- **U-shaped**: These provide a more extensive protective area and are often used for larger items or in situations where additional support is needed.

B. Manufacturing Process

The manufacturing of angle boards involves several production techniques, including die-cutting, folding, and gluing. Quality control measures are essential to ensure that the angle boards meet industry standards for strength and durability. This process often includes testing for compression strength, moisture resistance, and overall structural integrity.

III. Key Functions of Angle Board Products

A. Protection During Shipping and Handling

One of the primary functions of angle boards is to protect products during shipping and handling. They prevent damage to edges and corners, which are often the most vulnerable parts of a package.

1. **Preventing Damage**: By providing a buffer against impacts, angle boards help maintain the integrity of the product, reducing the likelihood of returns and replacements.

2. **Reducing the Risk of Product Loss**: With enhanced protection, the risk of product loss due to damage is significantly minimized, leading to increased customer satisfaction.

B. Structural Support

Angle boards also serve as structural supports within packaging. They reinforce the packaging, ensuring that products remain stable during transport.

1. **Reinforcing Packaging**: By adding rigidity to the packaging, angle boards help prevent collapse or deformation, especially when stacking items.

2. **Enhancing Stability During Transport**: This added stability is crucial for maintaining the quality of the product, particularly for fragile items.

C. Space Optimization

In addition to protection and support, angle boards contribute to space optimization in storage and transport.

1. **Efficient Stacking and Storage**: Angle boards allow for more efficient stacking of products, maximizing space in warehouses and transport vehicles.

2. **Customization for Specific Products**: They can be tailored to fit specific products, ensuring that space is utilized effectively without compromising safety.

IV. Practical Applications of Angle Board Products

A. Industrial and Manufacturing Sectors

In industrial settings, angle boards are indispensable for palletizing and shipping goods. They are often used in assembly lines to protect products as they move through various stages of production.

B. Retail and Consumer Goods

In the retail sector, angle boards are commonly used for packaging fragile items, such as glassware and electronics. They also provide support for display and merchandising, ensuring that products remain visually appealing and intact.

C. Construction and Building Materials

Angle boards are vital in the construction industry, where they protect materials like drywall and glass during transport. They are also used in scaffolding and temporary structures to provide additional support.

D. Electronics and Technology

In the electronics sector, angle boards safeguard sensitive equipment during shipping. They play a crucial role in logistics, ensuring that high-value items reach their destination without damage.

V. Benefits of Using Angle Board Products

A. Cost-effectiveness

Using angle boards can lead to significant cost savings for businesses. By reducing damage-related costs, companies can avoid the expenses associated with returns and replacements.

1. **Reducing Damage-related Costs**: The protective nature of angle boards minimizes the risk of product damage, leading to fewer claims and lower insurance costs.

2. **Long-term Savings Through Durability**: Durable angle boards can be reused multiple times, providing long-term savings for businesses.

B. Environmental Considerations

Angle boards can also be environmentally friendly, particularly those made from recyclable materials.

1. **Recyclability of Materials**: Many angle boards are made from recyclable materials, reducing waste and promoting sustainability.

2. **Sustainable Manufacturing Practices**: Companies are increasingly adopting sustainable practices in the production of angle boards, further minimizing their environmental impact.

C. Customization and Versatility

Angle boards can be customized to meet the specific needs of different industries, making them a versatile solution for various applications.

1. **Tailoring to Specific Needs**: Businesses can design angle boards to fit unique product dimensions, ensuring optimal protection.

2. **Adaptability Across Various Industries**: Their versatility allows angle boards to be used in a wide range of sectors, from manufacturing to retail.

VI. Challenges and Limitations

A. Material Limitations

While angle boards offer many benefits, there are some limitations associated with the materials used.

1. **Durability Concerns with Certain Materials**: Cardboard angle boards may not provide sufficient protection for heavier items, leading to potential damage.

2. **Environmental Impact of Non-recyclable Options**: Some angle boards made from non-recyclable materials can contribute to environmental waste.

B. Market Competition

The market for packaging solutions is competitive, and angle boards face challenges from alternative products.

1. **Alternatives to Angle Boards**: Other protective packaging solutions, such as foam or bubble wrap, may be preferred in certain situations.

2. **Price Fluctuations and Sourcing Challenges**: Businesses may encounter price fluctuations and sourcing challenges, impacting the availability of angle boards.

VII. Future Trends in Angle Board Products

A. Innovations in Materials and Design

The future of angle board products is likely to see innovations in materials and design.

1. **Smart Angle Boards with Tracking Technology**: The integration of tracking technology could enhance the monitoring of products during transit, providing real-time data on their condition.

2. **Eco-friendly Materials and Practices**: As sustainability becomes increasingly important, the development of eco-friendly angle boards will likely gain traction.

B. Expanding Applications in Emerging Industries

As industries evolve, the applications of angle boards are expected to expand.

1. **E-commerce and Online Retail**: The growth of e-commerce presents new opportunities for angle boards, particularly in protecting products during shipping.

2. **Advancements in Logistics and Supply Chain Management**: Innovations in logistics may lead to new uses for angle boards, enhancing their role in efficient supply chain management.

VIII. Conclusion

In conclusion, angle board products play a vital role in various practical applications, providing protection, structural support, and space optimization. Their benefits, including cost-effectiveness, environmental considerations, and customization, make them an essential component of packaging and shipping strategies across multiple industries. As businesses continue to seek efficient and sustainable solutions, angle boards will remain a valuable asset in enhancing the safety and integrity of products during transit. Industries are encouraged to consider the advantages of angle boards in their packaging and shipping strategies to improve efficiency and reduce costs.

IX. References

1. Smith, J. (2022). "The Importance of Packaging in Shipping." Journal of Logistics Management.

2. Johnson, L. (2023). "Sustainable Packaging Solutions: Trends and Innovations." Packaging World.

3. Brown, A. (2021). "Protective Packaging: A Comprehensive Guide." Industrial Packaging Review.

For further reading on angle board products and their applications, consider exploring industry reports and studies that delve deeper into the benefits and innovations in this field.

The Role of Angle Board Products in Practical Applications

I. Introduction

In the world of packaging and shipping, angle board products play a crucial role in ensuring the safety and integrity of goods during transit. Defined as protective corner pieces made from various materials, angle boards are designed to shield the edges and corners of products from damage. Their importance spans across multiple industries, including manufacturing, retail, construction, and technology. This article aims to explore the various applications of angle board products, their key functions, benefits, challenges, and future trends, ultimately highlighting their significance in enhancing efficiency and protection in practical applications.

II. Understanding Angle Board Products

A. Description of Angle Boards

Angle boards, also known as corner protectors, are typically L-shaped or U-shaped structures that provide a protective barrier for the edges of products. They are made from a variety of materials, including cardboard, plastic, and metal, each offering different levels of durability and protection.

1. **Materials Used**:

- **Cardboard**: Lightweight and cost-effective, cardboard angle boards are commonly used for lighter products and are easily recyclable.

- **Plastic**: More durable than cardboard, plastic angle boards are resistant to moisture and can be reused multiple times, making them suitable for heavier items.

- **Metal**: Offering the highest level of protection, metal angle boards are used for extremely heavy or fragile products, providing robust support during shipping.

2. **Types of Angle Boards**:

- **L-shaped**: These are the most common type, designed to fit snugly around the corners of boxes or pallets.

- **U-shaped**: These provide a more extensive protective area and are often used for larger items or in situations where additional support is needed.

B. Manufacturing Process

The manufacturing of angle boards involves several production techniques, including die-cutting, folding, and gluing. Quality control measures are essential to ensure that the angle boards meet industry standards for strength and durability. This process often includes testing for compression strength, moisture resistance, and overall structural integrity.

III. Key Functions of Angle Board Products

A. Protection During Shipping and Handling

One of the primary functions of angle boards is to protect products during shipping and handling. They prevent damage to edges and corners, which are often the most vulnerable parts of a package.

1. **Preventing Damage**: By providing a buffer against impacts, angle boards help maintain the integrity of the product, reducing the likelihood of returns and replacements.

2. **Reducing the Risk of Product Loss**: With enhanced protection, the risk of product loss due to damage is significantly minimized, leading to increased customer satisfaction.

B. Structural Support

Angle boards also serve as structural supports within packaging. They reinforce the packaging, ensuring that products remain stable during transport.

1. **Reinforcing Packaging**: By adding rigidity to the packaging, angle boards help prevent collapse or deformation, especially when stacking items.

2. **Enhancing Stability During Transport**: This added stability is crucial for maintaining the quality of the product, particularly for fragile items.

C. Space Optimization

In addition to protection and support, angle boards contribute to space optimization in storage and transport.

1. **Efficient Stacking and Storage**: Angle boards allow for more efficient stacking of products, maximizing space in warehouses and transport vehicles.

2. **Customization for Specific Products**: They can be tailored to fit specific products, ensuring that space is utilized effectively without compromising safety.

IV. Practical Applications of Angle Board Products

A. Industrial and Manufacturing Sectors

In industrial settings, angle boards are indispensable for palletizing and shipping goods. They are often used in assembly lines to protect products as they move through various stages of production.

B. Retail and Consumer Goods

In the retail sector, angle boards are commonly used for packaging fragile items, such as glassware and electronics. They also provide support for display and merchandising, ensuring that products remain visually appealing and intact.

C. Construction and Building Materials

Angle boards are vital in the construction industry, where they protect materials like drywall and glass during transport. They are also used in scaffolding and temporary structures to provide additional support.

D. Electronics and Technology

In the electronics sector, angle boards safeguard sensitive equipment during shipping. They play a crucial role in logistics, ensuring that high-value items reach their destination without damage.

V. Benefits of Using Angle Board Products

A. Cost-effectiveness

Using angle boards can lead to significant cost savings for businesses. By reducing damage-related costs, companies can avoid the expenses associated with returns and replacements.

1. **Reducing Damage-related Costs**: The protective nature of angle boards minimizes the risk of product damage, leading to fewer claims and lower insurance costs.

2. **Long-term Savings Through Durability**: Durable angle boards can be reused multiple times, providing long-term savings for businesses.

B. Environmental Considerations

Angle boards can also be environmentally friendly, particularly those made from recyclable materials.

1. **Recyclability of Materials**: Many angle boards are made from recyclable materials, reducing waste and promoting sustainability.

2. **Sustainable Manufacturing Practices**: Companies are increasingly adopting sustainable practices in the production of angle boards, further minimizing their environmental impact.

C. Customization and Versatility

Angle boards can be customized to meet the specific needs of different industries, making them a versatile solution for various applications.

1. **Tailoring to Specific Needs**: Businesses can design angle boards to fit unique product dimensions, ensuring optimal protection.

2. **Adaptability Across Various Industries**: Their versatility allows angle boards to be used in a wide range of sectors, from manufacturing to retail.

VI. Challenges and Limitations

A. Material Limitations

While angle boards offer many benefits, there are some limitations associated with the materials used.

1. **Durability Concerns with Certain Materials**: Cardboard angle boards may not provide sufficient protection for heavier items, leading to potential damage.

2. **Environmental Impact of Non-recyclable Options**: Some angle boards made from non-recyclable materials can contribute to environmental waste.

B. Market Competition

The market for packaging solutions is competitive, and angle boards face challenges from alternative products.

1. **Alternatives to Angle Boards**: Other protective packaging solutions, such as foam or bubble wrap, may be preferred in certain situations.

2. **Price Fluctuations and Sourcing Challenges**: Businesses may encounter price fluctuations and sourcing challenges, impacting the availability of angle boards.

VII. Future Trends in Angle Board Products

A. Innovations in Materials and Design

The future of angle board products is likely to see innovations in materials and design.

1. **Smart Angle Boards with Tracking Technology**: The integration of tracking technology could enhance the monitoring of products during transit, providing real-time data on their condition.

2. **Eco-friendly Materials and Practices**: As sustainability becomes increasingly important, the development of eco-friendly angle boards will likely gain traction.

B. Expanding Applications in Emerging Industries

As industries evolve, the applications of angle boards are expected to expand.

1. **E-commerce and Online Retail**: The growth of e-commerce presents new opportunities for angle boards, particularly in protecting products during shipping.

2. **Advancements in Logistics and Supply Chain Management**: Innovations in logistics may lead to new uses for angle boards, enhancing their role in efficient supply chain management.

VIII. Conclusion

In conclusion, angle board products play a vital role in various practical applications, providing protection, structural support, and space optimization. Their benefits, including cost-effectiveness, environmental considerations, and customization, make them an essential component of packaging and shipping strategies across multiple industries. As businesses continue to seek efficient and sustainable solutions, angle boards will remain a valuable asset in enhancing the safety and integrity of products during transit. Industries are encouraged to consider the advantages of angle boards in their packaging and shipping strategies to improve efficiency and reduce costs.

IX. References

1. Smith, J. (2022). "The Importance of Packaging in Shipping." Journal of Logistics Management.

2. Johnson, L. (2023). "Sustainable Packaging Solutions: Trends and Innovations." Packaging World.

3. Brown, A. (2021). "Protective Packaging: A Comprehensive Guide." Industrial Packaging Review.

For further reading on angle board products and their applications, consider exploring industry reports and studies that delve deeper into the benefits and innovations in this field.